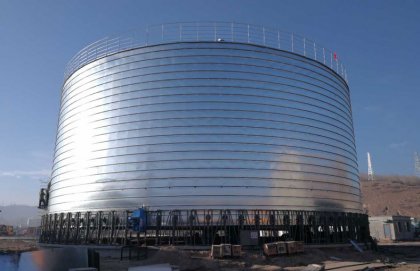

Flat bottom silo

The flat bottom silo has a flat service which means it can gives a full support to the silo. The floor design of the steel silo is decided by the material that stored in the silo. In flat bottom silos, air slides can be bolted onto the plinths cast into the floor or bolted directly to the silo floor. The flat bottom silo is suitable for cement storage, fly ash storage and other materials that requires fluidity system. The flat bottom silo is the most popular and cost effective silo because of it’s wild application. The flat bottom silo can be designed to meet the requirements of our customers. As for grain storage silo, it needs to accept loads from mixing, condition and unloading equipments, equipment floors will be added to the steel silo plans.

Hopper bottom silo

Hopper bottom silo is also called cone bottom silo. Which is different from the flat bottom silo in shape. Hopper bottom steel silo is always a better choice for those who want small silos.The hopper bottom silo has a complete drainage and the configuration of the hopper silo depends on the type of material that being stored in the silo. The hopper bottom silo can be designed according to our customers’ needs for grain and food storage.

Which one do we choose, flat bottom silo or hopper bottom silo

From the aspect of piratical, it is better to choose hopper bottom silo, because of the special hopper design, makes it has the advantage of no stock and do not need to configure clearance equipment. However, the hopper bottom steel silo has it’s limitation from the aspect of economic.

The fact shows that hopper bottom steel silo has it’s limitation in design, the diameter of hopper bottom silo is no more than 10ms and the capacity is no more than 1500tons. The size of hopper bottom steel silo is depend on the natural flow angle of the storing material. That is to say, the smaller the natural flow angle of the material, the greater the height of the hopper bottom. Normally, the natural flow angle of many material is general 40 degrees, such as grain and other material. When the steel silo has a large diameter, the upper beam of the foundation support structure will have to be greatly increased.

Let’s see this example. A hopper bottom silo with the diameter of 15ms, in order to support the silo and meet the requirements of the equipment under the silo, the height of the upper ring beam of the foundation support structure should be at least 8m. compared to the same capacity of a flat bottom silo, the basic cost of hopper bottom silo is more than 40% than hopper bottom silo.

As we summarized, hopper bottom silo is suitable for silos with the diameter of no more than 10ms. Flat bottom silo is suitable for large capacity storage. The specific detail is determined by the customer, of course, our engineer will give you the best plan and advice.