About Agico Cement Lipp silo

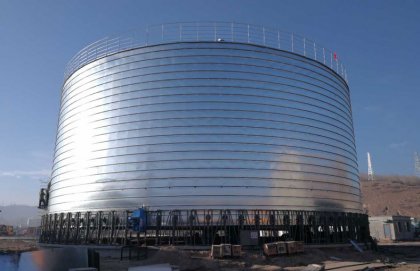

Lipp steel silo is also called Spiral steel silo. As a storage tool, the main role of the steel silo is to storage grain, fly ash, slag powder, cement, chemical and so on.

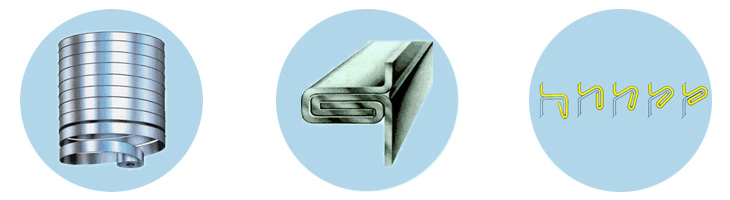

Lipp steel silo double seam technology is a patented technology of the German technical engineer called Xavef Lipp. It applies the principle of metal plastic working hardening and thin shell structure. Use special technology and equipment to apply 2 to 4 mm thick galvanized steel (or stainless steel). According to the “spiral, double-seam and cleanching" process to create a Lipp steel storage silo with a volume of 100 to 5000 m3.

Lipp steel silo, also known as spiral steel silo, as the name implies, the whole silo body is spiraled and concatenated by using professional equipment. The Lipp technical silo has a short construction period, a relatively low cost, and a good quality. It occupies a small area, has no scaffolding on the floor to install the silo top, and is easy to construct. In recent years, due to the superior performance and other advantages of Lipp silo, the steel silos have quickly occupied the silo market. Steel silos now are wildly used in grain storage and other industrial powder storage.

Preparation of steel storage silo

Customized design

Once the order is settled. Generally, customers need to provide their design drawing of the steel silo. We can also provide free design for customers. Customers are required to provide our designing team detail data such as material to contain, field scale, special demand and so on. The design drawing must be confirmed by both customers and our company to make sure the safety and the veracity, also to avoid unnecessary divergence.

Preferential Capacity Table

This is a table that summarized by our technology with years experience and test, this table is a reference to these who have no idea how large their want their silos to be. According to this table. The standard silo is both aesthetically and practically.The minimum diameter of the steel storage silo is 3 meters and the maximize is 28 meters. The angle of the conical top is recommend to be 15°.

|

6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 75 | 88 | 100 | 113 | 126 | 138 | 151 | 163 | 176 | 188 | 201 | |||||||||

| 5 | 118 | 137 | 157 | 177 | 196 | 216 | 236 | 255 | 275 | 295 | 314 | 334 | 353 | |||||||

| 6 | 226 | 254 | 283 | 311 | 339 | 367 | 396 | 424 | 452 | 480 | 509 | |||||||||

| 7 | 385 | 423 | 462 | 500 | 539 | 577 | 615 | 654 | 693 | 731 | 770 | |||||||||

| 8 | 502 | 553 | 603 | 653 | 703 | 754 | 804 | 854 | 904 | 955 | 1005 | 1056 | 1106 | |||||||

| 9 | 763 | 827 | 890 | 954 | 1017 | 1081 | 1145 | 1208 | 1272 | 1336 | 1400 | |||||||||

| 10 | 942 | 1021 | 1099 | 1178 | 1256 | 1335 | 1413 | 1492 | 1570 | 1649 | 1728 | |||||||||

| 11 | 1140 | 1235 | 1330 | 1425 | 1520 | 1615 | 1710 | 1805 | 1900 | 1996 | 2091 | |||||||||

| 12 | 1356 | 1470 | 1583 | 1696 | 1808 | 1922 | 2035 | 2148 | 2261 | 2374 | 2487 | 2601 | 2714 | 2827 | ||||||

| 13 | 1592 | 1725 | 1857 | 1990 | 2122 | 2255 | 2388 | 2521 | 2653 | 2786 | 2919 | 3053 | 3186 | 3318 | ||||||

| 14 | 2308 | 2462 | 2616 | 2769 | 2923 | 3077 | 3231 | 3385 | 3559 | 3695 | 3848 | |||||||||

| 15 | 2649 | 2826 | 3003 | 3179 | 3356 | 3533 | 3709 | 3886 | 4062 | 4241 | 4418 | |||||||||

| 16 | 3617 | 3818 | 4019 | 4220 | 4421 | 4624 | 4825 | 5027 | ||||||||||||

| 17 | 4048 | 4310 | 4537 | 4764 | 4991 | |||||||||||||||

| 18 | 4578 | 4832 | 5087 | 5341 | 5595 | |||||||||||||||

| 19 | 5101 | 5384 | 5668 | 5951 | 6234 | |||||||||||||||

| 20 | 5652 | 5966 | 6280 | 6594 | 6908 | |||||||||||||||

| 22 | 6842 | 7223 | 7603 | 1982 | 8362 | |||||||||||||||

| 24 | 8143 | 8595 | 9048 | |||||||||||||||||

| 25 | 8835 | 9326 | 9817 |

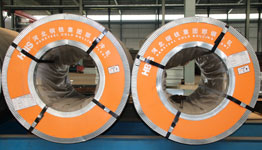

Semi-finished steel parts

Because of filed limited, some welded parts will be pre-manufactured and packed in our factory before delivery to best save cost on construction site and shorten construction duration. These may include all accessory parts, steel plate and other parts. Our steel plate and all accessories are all made of galvanized steel sheet.

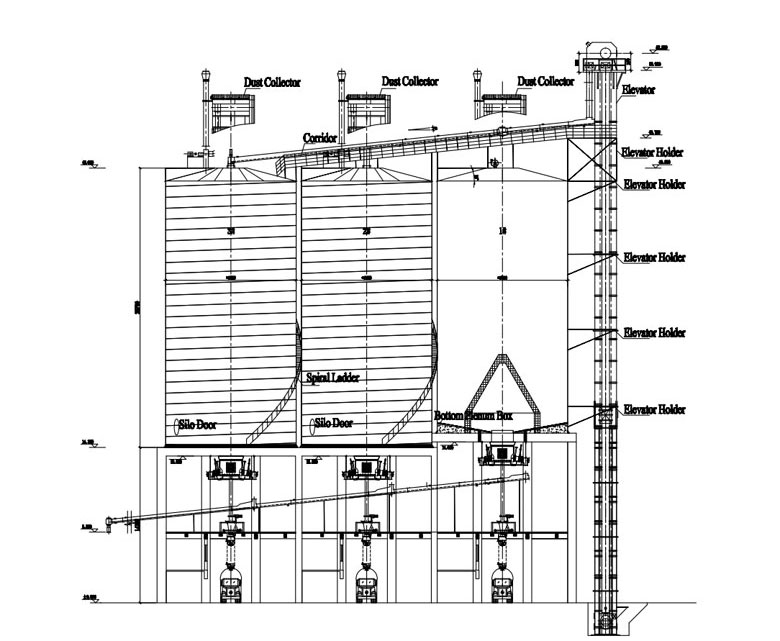

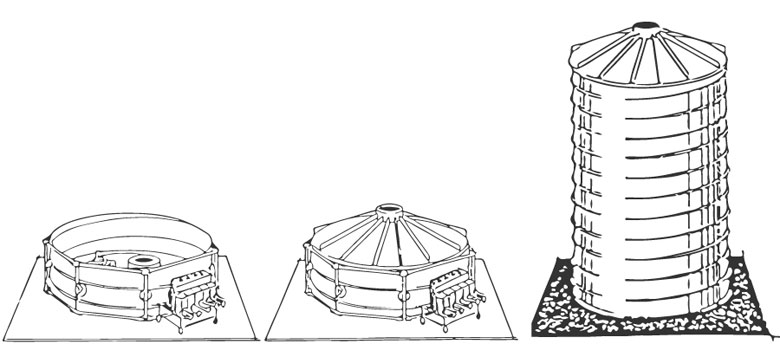

On site construction procedure of Flyer steel storage silo

There are seven steps for on site construction procedure. The core of the construction is by using our spiral folding technology, it is also a symbol of Lipp silo unique technology which is different from other type of steel storage silo.

steel silo on site construction

Equipment location

The first thing to do is locate all the necessary equipment on the decided on site location. There should be prepared concrete base or steel frame base. The selection of base is depend on different elements. P.S. The base construction does not contained in our bossiness scope. The diameter of the base is according to the size of the steel storage silo. When all the equipment are settled in the correct place, the construction of steel storage silo process can be started.

Silo bending

First of all, Use the decoiling machine to decoil the galvanized steel strip coils. During the construction process, the decoiled steel strip will be delivered to the forming machine. The forming machine will bend the steel strips to a certain radian according to the request of the target steel storage silo. With the help of silo forming machine, the bended steel strips after the bending machine can be seamed together to the double-seam system.When the steel galvanized steel strip coils formed into double system, we need to use supporting bears to support the whole construction of the silo and make sure with the help of bearing support, the whole structure can keep rising.

Silo roof installation

Accompanying with the rising of the whole body, when the main body of the silo raises to a certain height, normally 2 meters high. Our workers will start to install the roof of the silo. Because the height of silo is range from 6 meters to 25meters, which is too high that the safety of workers can not be guaranteed. After the installation of the roof, the forming and bending will continue and the silo will keep raising.

Stiffeners fixing

With the raising of the silo, our worker will start to weld the steel stiffeners. Steel stiffeners are used to help the structure of the silo more stable and makes the silo lasting long and hard to collapse. We also use double stiffener plates to ensure the stability of stiffeners.

Silo lifting

For some small diameters steel storage silos or silos built on the ground. We usually use a crane to lift the whole body to load the steel silo on the basement. The main part of the silo has been complete.

Auxiliary equipment installation

After finished the silo body construction. Customers will always order some auxiliary equipment fixed on the silo that used to maintain and check the condition of the silo. There are some necessary auxiliary equipment, such as roof air vent, used to keep the air flowing, the ladder system, build by the side of the silo, and other auxiliary to make up the whole silo system.

If you get any question, you can send us e-mail, we are wiling to answer your questions.