Development of grain silo

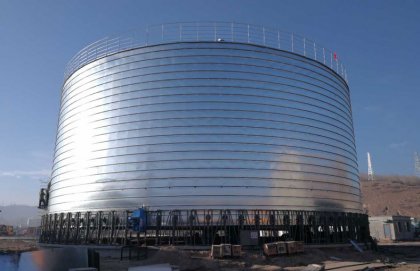

The steel silo is made of galvanized steel or corrugated steel and can be divided into welding silo, assembly silo and spiral silo. After the 1960s, thin-walled steel silos were rapidly developed in countries around the world, and China began to build a large number of grain silos after the 1980s. The galvanized steel silo has the advantages of light weight, low basic requirements, relatively low engineering cost, short construction period, high automation, high degree of mechanization, convenient consumption and high efficiency. However, the warehouse wall is thin, the grain layer is deep, it is easy to cause condensation, and the inspection is difficult. In addition, when the warehouse is not paid attention to the sealing of the warehouse, people begin to doubt whether it can safely store grain. In the research and practice of people's use for more than ten years, they gradually recognized and solved these problems, and recognized the advantages of thin-walled steel silos, especially since the 1970s, they have been developed abroad. After the 1990s, China's steel silos construction has achieved unprecedented development. With the development of China's grain management technology and the modernization of grain bin management, steel silos will gradually become the main warehouse type for bulk grain storage.

Grain storage silo performance

- The grain storage technology is continuously improved, and the degree of automation and mechanization is high. Due to the continuous development and improvement of the current grain storage and transportation process, cleaning and dust removal system, grain detection system, multi-functional ventilation circulation fumigation process and supporting equipment of the steel silo, it is beneficial to Improve the grain quality of the warehouse, realize the modern management of the granary, and provide a favorable guarantee for the long-term grain storage safety of the steel silo.

- The spiral grain silo, with tight bite and good sealing, which is conducive to food storage. It is widely used, in addition to storing grain and granular materials, it can also store liquid materials such as water and edible oil. At present, the steel silos consumed by the grain sector in China mainly store wheat, rice, soybeans and corn.

- Improved performance of process equipment, providing reliable means for storage management, good transportation process, cleaning dust removal system and equipment, not only improving efficiency, but also greatly improving the quality of grain entering the warehouse, reducing the risk of dust explosion, for safe storage The grain laid the foundation. Food testing, ventilation and fumigation systems are reliable means of ensuring the safety of stored grain. At present, most of the new grain storage silos are equipped with temperature measurement and ventilation systems, which can detect food heating in a timely manner, adopt ventilation measures, cool down the temperature, balance the grain temperature, improve the food hot and humid environment, and improve the stability of the grain storage; some are also equipped Fumigation system, circulation fumigation kills pests and ensures safe storage of grain.

What you need to pay attention during the use of grain silo

Safe storage of steel silos The problem of steel silos is due to the thin wall, large internal and external temperature difference, condensation of food, arching and even mildew. People suspect that it is safe to store grain. Practice has proved that as long as it is managed well, the safety of grain storage is guaranteed. In general, grain moisture and impurities in storage are important factors affecting safe grain storage. Therefore, try to improve the dust removal process, the grain impurities should be controlled below 1.0%; strictly control the grain moisture, generally not more than 13%, such as water is higher than 13.5%, should be timely ventilation and cooling; timely circulation, follow the principle of first in, first out . After the grain is put into the warehouse, although the warehouse wall is thin, the temperature difference is easy to form inside and outside the warehouse, but the grain is a bad conductor of heat, and only the grain temperature within 300 mm from the warehouse wall changes. At the same time, the heat absorption is fast and the heat dissipation is fast. On a sunny day, the grain temperature is the highest at 3:00 pm, but the grain temperature at 7:00 pm is basically restored. The installation of the grain inspection system provides convenient and detailed data for daily grain temperature testing and management. Once the grain temperature changes, it can be properly disposed of. In the top of the warehouse, the grain surface is prone to condensation, and it is necessary to install an axial fan or an exhaust device at the top of the warehouse. The mechanical ventilation device is installed at the bottom of the warehouse, and the ventilation channel is an effective measure for safe grain storage.

According to the data introduction and investigation, it is confirmed that as long as the performance requirements of grain storage for granaries are met, the management of grain storage is strengthened, and effective safe grain storage measures are adopted, the steel silo can be used as a long-term storage granary, and the safe storage period can reach 3 years for rice and corn. In terms of safety, it can be stored safely for more than one year. If the steel silo is insulated and the supporting facilities and technology are perfected, the grain storage time will be longer. In addition, in 998, the State Food Bureau Zhengzhou Research and Design Institute was commissioned by the State Planning Commission to investigate the state of safe storage of steel silos in the country. According to the investigation, some steel silo users have gradually improved the management of grain storage due to proper ventilation and cleaning measures. The longest safe storage period of wheat has exceeded 3 years; however, some units are equipped with supporting technology and management. Insufficient, the safe storage period of steel storage grain is only 6 months.