Introduction of coal storage silo

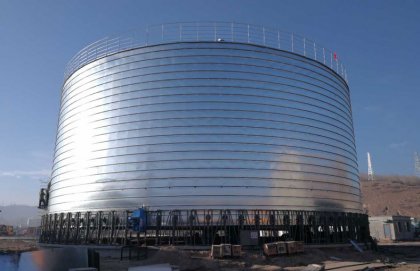

Coal storage silo are used in some power plants and coal mines. Concrete silo and steel silo are both wildly used in coal storage, concrete silos cost more money and time to built one. Since lipp coal storage silo is more popular and has more advantage than concrete silo. It is wildly used in the area of grain and oil, brewing, building materials, environmental protection, chemical industry, energy and other industries.Lipp Silo is invented by a German named Xaver Lipp. This silo technology was introduced to China in 1960s and 1970s, and start its application in the field of cement building materials in 1980s. Now it has been widely used in cement plant, grinding station, hydropower station, thermal power station, and cement transfer depot.

Features of coal storage silo

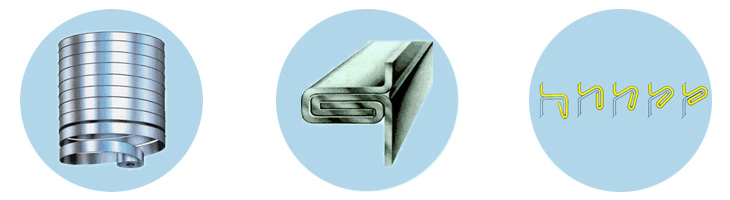

- Long service life. During the process of Flyer coal storage silo, special equipment was used in the whole process which can ensure the stability of the silo, his greatly strengthened the carrying capacity of the silo body, and granted the silo high integral strength.

- Good sealing performance. Thanks to the double seam system that makes the silo sealed well and can prevent leakage of all material from caking and hardening.

- Short construction period. Buy using lipp shaping and bending equipment, the speed of construction can reach 3m-5m per minute, which makes the construction period very short. For example, to built a 15meters tall coal silo, it only needs 8-10days. Because of it’s short time construction period, we can also save a lot of labor cost and reduce the budget of the silo.

- Small footprint. The coal silo takes small places than other kind of silos. Lipp Silo’s height and diameter can be arbitrarily adjusted within a large range. Comparably small coverage that could narrow the separation distance between two silos down to 500mm for maximized space utilization.

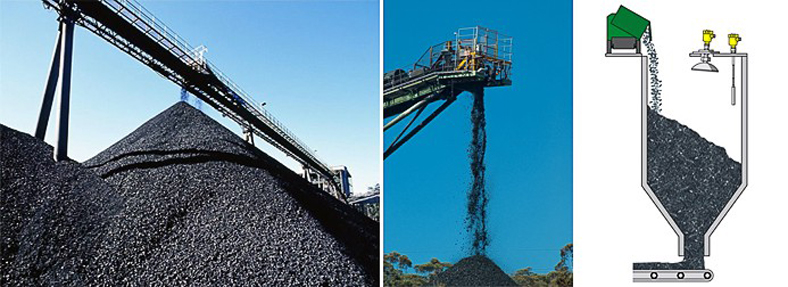

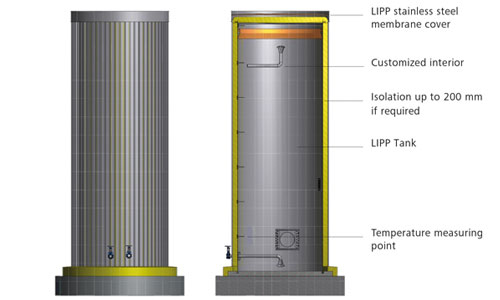

A complete set of coal storage silo

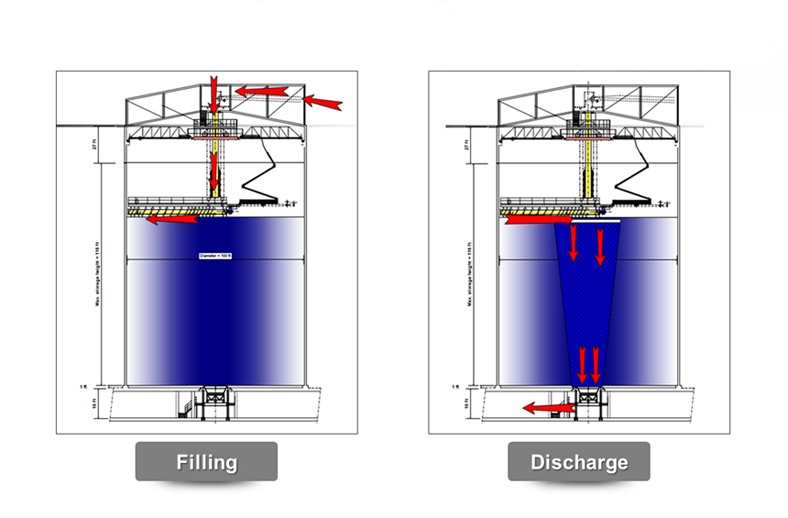

Let’s have a deep discovery about the working process of a coal storage silo.

Let’s start from the top to the bottom.

Another kind of part called e sensor or some times we use radio-frequency capacitive material level limit switch both on the top and bottom of the coal silo. With these machines, we can know clearly about the the height of coal that stored in the silo and the dust condition, which helps us to know clear about the condition of the coal and the stock of the coal.