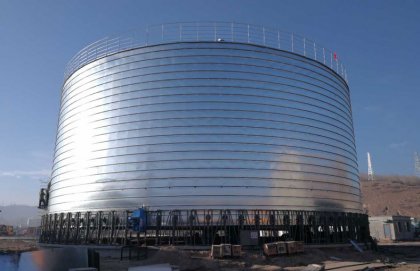

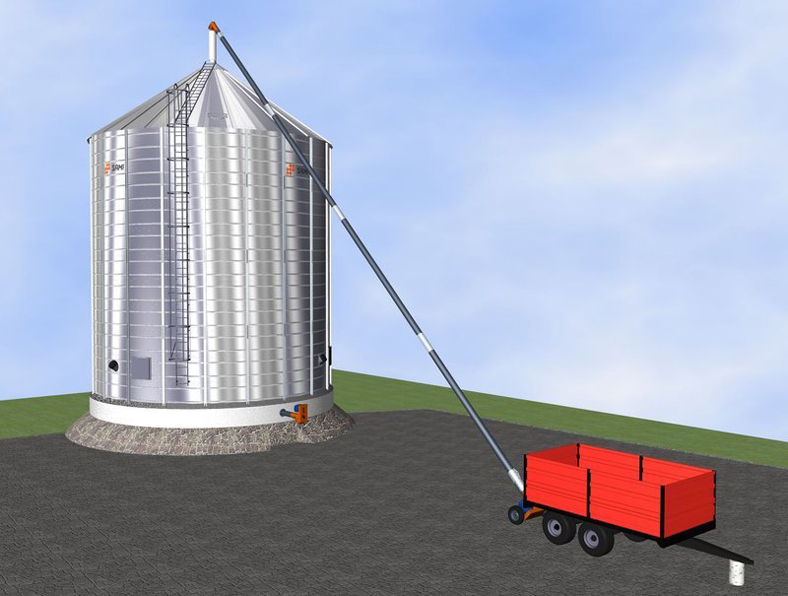

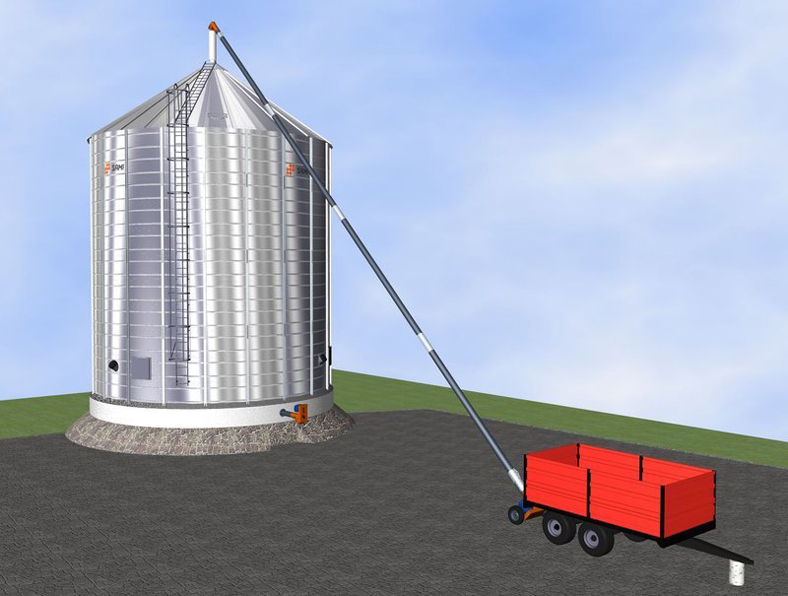

Flyer is a steel silo manufacturer and supplier in China for over 20 years, hence we can provide our customers who want customsize silos or alrerady have different types of silos.

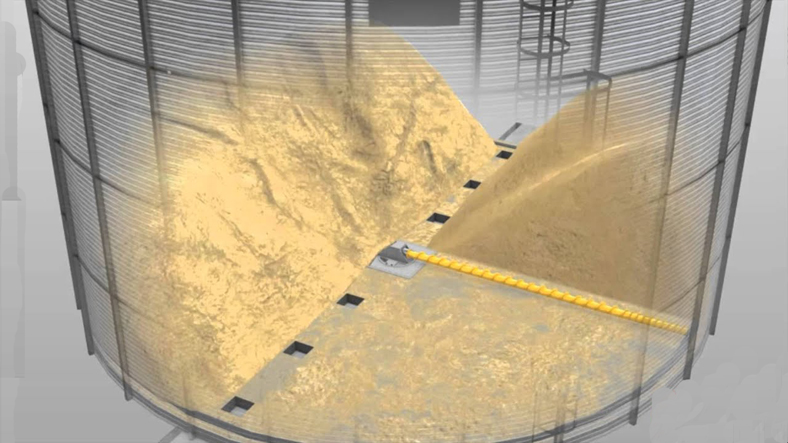

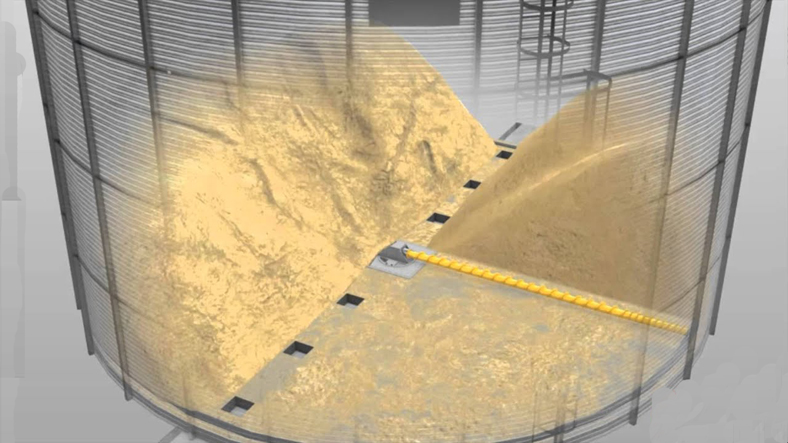

The large-scale steel silo discharge adopts pneumatic conveying mode, and the fluidity of the material is the key to whether the steel silo can be discharged normally. Material flow is subject to a variety of effects. The accumulation of materials for a long time, the humidity of the material is large, the outside air moisture enters the warehouse, the bottom of the reservoir is wet, and some improper operations are the reasons for the deterioration of material flowability.

Why the discharing rate important to steel silo?

The steel silo discharging rate refers to the percentage of material discharged from the steel silo as a percentage of the total material, also known as the emptying rate. The emptying rate directly reflects the advantages and disadvantages of the practical performance of the steel silo, and is the main performance index of the steel silo. When the discharge condition of the steel silo deteriorates, the storage material of the storage accumulates more and more, and the increase of the accumulated material and the slowing of the discharge cause the effective fluidization volume of the steel silo to decrease, resulting in a low discharging rate. The low discharging rate not only makes the steel silo not play a good discharging effect, but also reduces the economic benefits of the steel silo utilization.The large-scale steel silo discharge adopts pneumatic conveying mode, and the fluidity of the material is the key to whether the steel silo can be discharged normally. Material flow is subject to a variety of effects. The accumulation of materials for a long time, the humidity of the material is large, the outside air moisture enters the warehouse, the bottom of the reservoir is wet, and some improper operations are the reasons for the deterioration of material flowability.

What will influence the dischaing rate of steel silo?

- The tonnage of the material is too large, the material level is too high, the material density is increased, the bottom of the reservoir is increased by the pressure of the storage material, the material is pressed against the bottom of the reservoir, and the fluidization performance is lowered. If the storage of the material is not carried out for a long time, the material in the warehouse is crushed to death, and the material is difficult to be given. This phenomenon generally occurs when the material is sold in the off-season, when the stock is much larger than the sales. In order to avoid compaction of materials for long-term storage, the steel warehouse should regularly use the external circulation pneumatic system to loosen the bottom material.

- The water content of the powdered material itself is too high, resulting in a decrease or failure of fluidization properties during discharge. In this regard, the user should strictly control the moisture content before the material is put into storage, and reduce the moisture content of the material to a minimum. The more dry the material, the better its fluidization activity and the more difficult it is to compact.

- The base layer of the bottom of the cement was not completely air-dried, and no effective moisture-proof measures were taken. The moisture at the bottom of the reservoir caused the humidity of the bottom material to be increased and bonded into blocks, which caused difficulties in the materials. In addition, some Party A's use of the unit is not uniform, the cone is naturally air-dried and requires early feeding, so the implementation of the moisture-proof measures at the bottom of the reservoir is particularly critical. Our company has decided to apply moisture-proof and waterproof materials on the surface of the guide cone to improve the dryness of the bottom of the reservoir. At the same time, the smooth and clean moisture-proof adhesive layer surface is more conducive to the material circulation.