Excellent technology and management

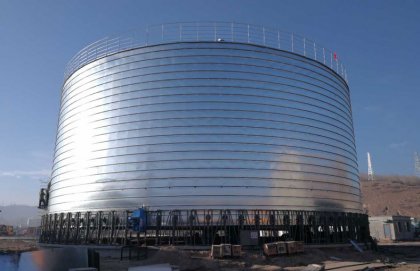

Each steel silo project must be equipped with the construction personnel as following: project manager, project engineer, engineering technician, engineering information officer, front-line management personnel, front line operators and so on. In the construction of steel silos, strictly accordant with the requirements of the specification, follow the highest standards for technical disclosure, pay close attention to process management. Flyer is a steel silo supplier with years of experience and an experienced construction team. With a strong back up of a technology team and strong company strength.Flyer steel silo company is responsible to every front line staff and is responsible to every client of ours. In the construction of the steel silo and supporting frame, the safety consciousness of the employees is upheld, life is loved, and safety is concerned. Safety is the source of happiness, safety is the guarantee of effectiveness. The quality of steel silo is as heavy as the mountain to motivate employees and urge them to pay attention to safety. Careful design is the soul of engineering quality. Standard construction is the foundation of project quality. Strict supervision is the key to project quality. Government supervision is the guarantee of project quality. The steel silo is highly constructive, requires a simple foundation, and is quick to construct, independent of weather conditions. After understanding the superior performance of the steel silo, users should pay attention to the following issues during construction.

The choice of steel silo materials

steel silo usually choose the ordinary type of steel, with Q235 as the best, easy to draw, and low cost. If the silo wall thickness of the silo is calculated to exceed the capacity of the equipment, low alloy steel is used instead of Q235. Silo silo panels are usually galvanized to meet corrosion protection requirements. Therefore, the galvanized layer has become an important indicator for the construction of the silo. It directly affects the service life of the silo. China's standards are in line with foreign standards and require a galvanizing amount of 400 g/m2. All our steel plates meet the standard and have a better quality.Choice of silo form

Second, the choice of silo form: The popular thin-walled silo is advantageous for both the squat silo and lipp silo. They have their own characteristics due to their different structural forms.Our company mainly provide the construction of Lipp silo.

Features of Lipp silo

- Using hot galvanized coil continuous undercut forming, the color is uniform;

- High airtight. It can store water, oil and other liquid materials;

- Due to the silo wall is smooth, the required thickness is larger than the assembly silo.

Features of assembly silo

- It can be used hot-dip galvanized coil, flat, can also use electro-galvanized sheet.

- All parts are standard components and replaceable. Users in the course of use, such as damage or corrosion, you can easily replace the damaged parts to extend the service life.

- It can be modified, demolition, especially for users of rental space is very suitable.

- It can achieve the form of external columns, the flow of food in the silo is more favorable.

- Air tightness is worse than lipp silo, but after the use of silicone sealant, airtight requirements can be achieved.

- Double-layer insulation structure can be conveniently realized with little increase in cost.

The basic form of steel silo selection

Flat bottom silo: general large-diameter silo application, need to be equipped with sweeping machine or manual clearance, this type of construction is relatively easy, lower cost .

Hopper bottom: Taking into account the self-flow of grains, the hopper bottom form is used in large numbers, and the hopper bottom is divided into three types: steel cone, semi-steel cone and cement cone. From the use of speaking, the three are not much different. , but there is a way to use backfill. Filling a conical bucket in the silo, although this method reduces the difficulty in the construction process, it wastes the material and capacity of the steel silo and increases the amount of civil engineering work.