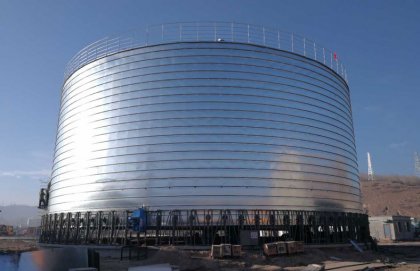

The steel silo has a long history and has a history of at least 100 years. At present, the storage range of China's steel silos has gradually become wider, involving food industry, brewing industry, coal industry, building materials industry, urban and rural areas and environmental protection industries. It is also capable of storing materials such as granules, powders, and liquids. It brings great convenience to life and brings good economic benefits to the country. Flyer, specializing in the research, development and construction of steel silos. Many people did not know how to control the temperature of the steel silo in the case of sudden changes in the external environment.

According to the relevant regulations of the state, during the use of the steel silo, the temperature and humidity of the materials inside the warehouse should be checked. According to the nature of the materials stored and the required storage time, corresponding precautions should be taken (such as downsizing and cooling). To ensure the safe storage of all kinds of materials, no deterioration.

In the area where the temperature is relatively low, properly select the appropriate low temperature resistance to prevent collapse accidents. Before the rainy season comes, we must carefully check the corrosion protection of the steel silo again, and we must deal with it regularly.

The steel silo ventilation air network system is designed by multiple specific pipelines and connected with the fan, which can quickly cool, dehumidify and remove dust in the warehouse, which ensures the quality of the grain in the warehouse and improves the added value of the product.

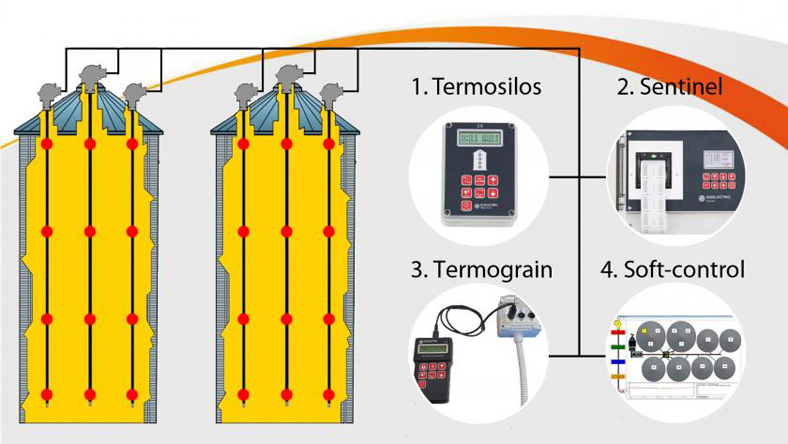

Let us learn how to control the temperature of the steel silo

In terms of design, we solved the technical barrier of the formation of cement in the inner wall of the steel silo. Effectively control the temperature of the steel silo in the temperature range of minus 50 ° to 160 °, the physical indicators in the cement steel silo unchanged. In the design, insulation, anti-corrosion and cold-proof measures are also adopted, and the positive pressure in the steel warehouse is used to balance the temperature. The setting and application of the thermal insulation material changes the influence of the temperature outside the steel silo on the temperature inside the steel silo. We have a lot of help in how to control the temperature.According to the relevant regulations of the state, during the use of the steel silo, the temperature and humidity of the materials inside the warehouse should be checked. According to the nature of the materials stored and the required storage time, corresponding precautions should be taken (such as downsizing and cooling). To ensure the safe storage of all kinds of materials, no deterioration.

In the area where the temperature is relatively low, properly select the appropriate low temperature resistance to prevent collapse accidents. Before the rainy season comes, we must carefully check the corrosion protection of the steel silo again, and we must deal with it regularly.

The advantages of silo ventilation system

It is no exaggeration to say that the ventilation system is the heart of the steel silo. Why do you say that? Because the ventilation system can quickly cool, dehumidify and dedust the grain in the steel silo, it can greatly ensure that the grain in the steel silo does not deteriorate! The specific working principle, followed by the state of the steel plate warehouse for everyone to do a detailed analysis!The steel silo ventilation air network system is designed by multiple specific pipelines and connected with the fan, which can quickly cool, dehumidify and remove dust in the warehouse, which ensures the quality of the grain in the warehouse and improves the added value of the product.

- The steel silo ventilation air network system overcomes the deficiencies of the prior art, and provides a steel silo ventilation air net system with high efficiency dust removal, temperature reduction and dehumidification.

- The steel silo ventilation air network system comprises a concrete base, a steel silo body, a warehouse cover, a through ventilation duct, an inner ventilation duct, an outer ventilation duct, a fan and a conveyor, wherein the steel silo body is arranged on the concrete base. The ventilation duct is interspersed between the steel silo body and the cover, the inner ventilation duct is arranged inside the steel silo body, the fan is connected by the outer ventilation duct and the bottom of the inserted ventilation duct, and the conveyor is arranged at the bottom of the steel silo body.

- The bottom of the steel silo body is provided with a conical funnel discharge port, and a discharge electromagnetic control valve is arranged at the outlet of the conical funnel discharge port, and the discharge electromagnetic control valve and the conveyor are parallel. The number of interspersed ventilation ducts is two, respectively, the left interspersed ventilation duct and the right interspersed ventilation duct, the inner ventilation duct top and the cover are connected, and are fixed at the center of the cover cover, the inner ventilation duct bottom and the interspersed ventilation duct are in the steel silo warehouse. The body is connected and connected to the fan through an external ventilation duct.

- At the same time, a tapered funnel is used to design and install the conveyor at the bottom of the steel silo body. First, it can ensure that all the grain in the warehouse body falls to the bottom. When filling, the grain can be completely filled. Second, the filling is quickly filled by the conveyor. Loading and conveying greatly improve the filling efficiency, saving time, labor and labor. The steel plate ventilation air network system is ingeniously designed, which is very suitable for large-scale promotion.