About chemicals storage silo

Chemicals storage silo, also known as chemicals spiral steel silo, chemical tank, is wildly used in chemical processing factory and chemical transport station. Chemical storage is different from grain storage or cement storage. When storing chemicals, there are a lot of factors that we need to take into consideration in case of chemical reaction happens. Chemicals storage silo can be divided into different sizes and shapes, and they can be used to stationary storage, processing, or other purposes. Chemical tanks can store gasoline, diesel, dimethylmethane, liquefied gas and other dry bulk chemicals. Chemicals spiral steel silos are applied in the area of industry, farm land and so on.

The under ground chemical storage tank is a good choice for maximizing use of chemical storage. Since the chemical tank is constructed under the ground, no matter under lawns or gasoline station. It is much safer when suffering from the risk of fire and explosion. But the under ground chemical storage tank also have disadvantages. The chemical storage tank may leakage and cause pollution to the water and soil, and cause serious damage to the citizens. Therefore, it is important to check the condition of the storage silo carefully before put into use.

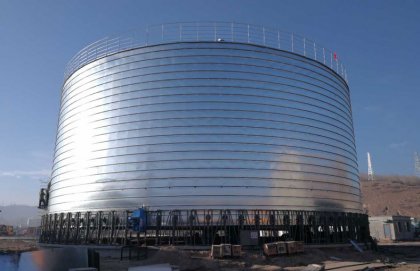

The above ground chemical spiral steel silo is a common seen storage tool in our daily life. It is suitable for storing chemicals and fuels in bulk. The above ground chemicals storage silo has the advantages of low cost and easy to install. Compared to the under ground chemicals storage tank, the above ground silo is easier to check, maintain and fix. The limitation of above ground steel silo is that it may easily influenced by fire or extreme weather.

How to prevent the chemicals storage silo from corrosion?

Chemicals can be solid, liquid, semisolid or semi liquid. Different chemicals have their own character, some of them are corrosion, so we need some special coating technologies that is applied in to the installation of chemicals storage tanks to resist corrosion. With the coating technology, it can prolong the service life of the steel silo and decrease the maintenance cost.Coating technologies include epoxy coating, glass fused-to-steel, high heat coatings, cold weather coatings and etc. Galvanized storage silo is also popular, and it is suitable for storing block or dry bulk chemicals. Epoxy coating is the most common technology not matter store liquid our dry bulk. When applied in use, epoxy coating comes to a good effect without any trace of breaking and tearing.

Therefore, when you use an old steel silo to store a material that never stored before, you need to test and inspect whether it is suitable or you need to spiry another kind of coating material. Be sure that the tank can resist the corrosion. Incorrect use of a tank may cause huge losses.

Coating the steel silo has the advantages of protecting the chemicals steel silo, saving the maintenance cost and prevent environment. Coating technology is a long term plan for factories. Both under ground and above ground steel silo may corrosion and leak material. It may not only case loosen to the business but also pollute the environment. The proper coating and maintenance can avoid these situation. And ensure the safety of our water and land.