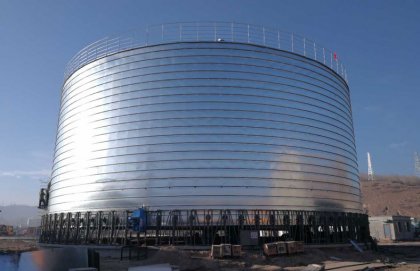

Introduction of lipp steel silo

Steel silos are storage tools that are welded, riveted, or combined with steel plate. Steel silos are mainly used to store cement, fly ash, chemical powder, slag, grain, industrial powder and other granular material. According to their different construction methods, stain steel silos are divided into welded steel silos, assembled steel silo and lipp spiral folded silo.Flyer is a spiral steel silo manufacturer in steel silo industry, and we can provide our customer lipp silo service from design to silo on site construction.

In this passage, we will introduce you construction process and advantages of spiral steel silo.

Material of lipp steel storage silo

To ensure the long service life and high quality of lipp steel silo, Flyer adopts high intense galvanized steel as silo construction material.The silo body is composed by galvanized steel plate, the galvanized steel plates are offered by Han Steel Group which is one of the largest steel material manufacturers and suppliers in China. The plate has the characteristic of anti corrosion, high strength, good looking, low cost and so on.

Different silos adopts different thickness of steel plate.

For different diameters of steel silos, designer will choose the proper thickness of steel plate. The thickness of steel plate ranges from 2mm to 6mm.

Equipment of building lipp steel storage silo

- Steel roller decoiling machine

- Steel plate bending machine

- Silo forming machine

- Silo supporting bears

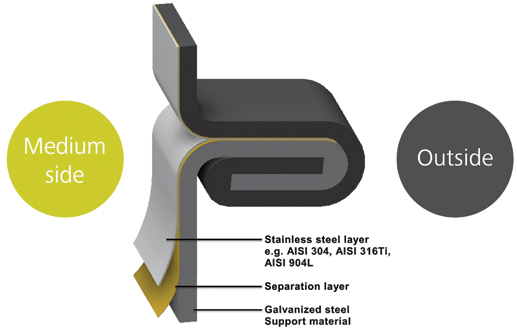

Double seam system

Double seam system is a unique feature of lipp steel silo. In the construction of silo installation process, the edge of galvanized steel plate are folded twice by our silo bending and forming machine. In this way, even the most aggressive material inside the silo can not find any leak to attack, the anti corrosion ability is beyond comparable.

Advantages of lipp steel storage silo

- Good overall performance, long service life. The anti corrosion galvanized steel plate and our professional can guarantee the quality and service life of these steel silos.

- Well air tightness performance, wild application. The silo is well sealed with our any leakage, the silo bites together with out gaps, so for grain storage, they can meet the requirement of insecticide and fumigation.

- Short construction period and low investment. Some of the parts can be prepared ready in the factory, as for on site installation, it doesn’t takes a lot of time and labor.

- Covers a small area, easy to manage. The space between two silos can be narrowed to 500mm.