Steel silo has a history of over 100 years, the form or the style of steel silo started from riveted silo, welded silo, assemblage silo to nowadays spiral silo, as knows as lipp silo. Steel silo originated from the early 20th century and wildly applied in western countries, in the late 1970s, steel silo almost take the place of other types silos in silo industry and become the winner. So far, 95% of grain storage silos in America are steel silos.

The development of steel silo

China was late when starting the steel silo technology in grain storage industry. Until 1982, an assemblage silo group constructed with galvanized corrugated sheet has been imported from the United States to Honghe Farm in Heilongjiang province which represent the earliest modern steel silo group in China. In the same year, by testing the steel silos that import from America, Heilongjiang Anqing steel factory build the first modern steel silo in China.

The steel industry in China has ushered a unprecedented development in the 1990s. The first complete and professional steel silo production technology line from America in the 21st century.

Zhengchang Group as the first who exported steel silo as a product in china, has absorbed the most advanced technology and designing software from the western countries. On the basis of the absorbed technology, Zhengchang Group implemented innovation and development to produce, manufacture and install assemble silo massively with better performance on strength, capability and security. It is now the representative of China’s international level on production, manufacture, and installation in steel silo industry, as well as the navigator of the entire steel silo industry around the world.

Nowadays, steel silos are wildly used in the storage of granule, powder, grain, oil, brewage, coal and building material and so on. Not limited in the area of industry, agriculture and environmental protection.

Three generations of steel silo

The First Generation

The first generation of steel silo is built according to the “National Design Specification for steel Concrete Silo GBJ77-85”. The silo wall is made of concrete or riveted steel. It is the product of the fast development of heavy industry in the late 20th century, but not suitable to prompt because of some technology problems. They are mainly used in local industries, cement design institutes, cement plants, and ready-mixed concrete companies and so on. The first generation steel silo has the capacity of about hundreds or thousands tons.

The Second Generation

The second generation steel silo is still common seen in many industries. It is called assemble steel silo. The technical features are following:

1. The assembled steel silo adopts hot galvanized steel sheet, all spare parts meet the national standard. The steel silo wall is replaceable which can prolong the service life.

2. The silo can be dismantled and reshipment, suitable for customer who rent rent places.

3. The size of the silo is customized. The assemble steel silo has improved a lot compared to the concrete silo in design and technology. However, it still inherits traditional techniques on mechanical structure and electrical controlling system. Unavoidably, there are technical defects such as the lack of intelligent control on loading, unloading and storing materials, backward technology and too much manual intervention. Therefore, it is hard to monitor the status of storage and preserve materials without deterioration over a long term.

The Third Generation

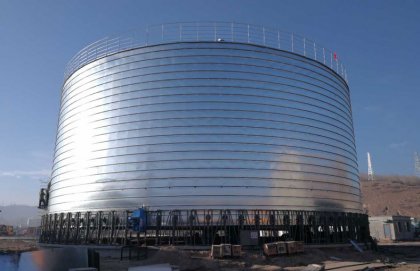

The third generation steel silo is the most advanced steel silo now in the world, which is also known as the spiral silo, it has the characteristic of following:

1. Advanced technology, the spiral silo adopts the most advanced German technology and equipment, the silo body is made of 30mm to 40mm thin galvanized sheet and the whole silo is light.

2. Good sealing performance and wild application. After the steel plate being bend, the seal condition is extremely good and can store liquid material. With it’s good performance, spiral silo has a wild application.

3. Comparably Short construction period, Competitive price and small coverage: Short duration can be guaranteed for our professional equipment can provide a 5m per minuets’ shaping and bending speed and no auxiliary facilities like scaffolding are needed during the whole procedure. The weight of spiral steel silo is just as heavy as 1 / 6 of the concrete silo, so that the cost for the entire project can be largely reduced. Comparably small coverage that could narrow the separation distance down to 500mm for maximized space utilization.