Autumn is the season for harvest. Did you make preparation for grain storage? Are your grain bins ready for your fall grains storage needs? Before you are into the frenzy of harvesting and storing your crop bounty, there is something you should do to keep away unexpected issues. Cleaning and maintaining your grain bins to make sure they are good in use.

To check the condition of the grain storage bin, we need to empty the grain bin and a visual inspection of the whole structure is needed. Start by walking the perimeter of the bin and accessing the condition of the grain bin basement.

To check the condition of the grain storage bin, we need to empty the grain bin and a visual inspection of the whole structure is needed. Start by walking the perimeter of the bin and accessing the condition of the grain bin basement.

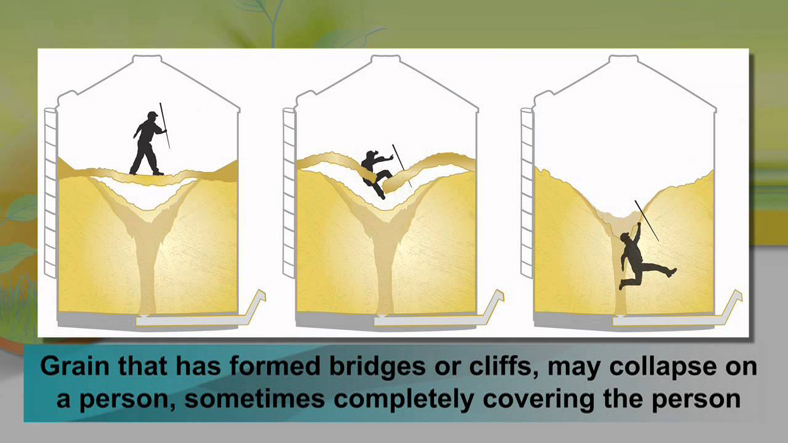

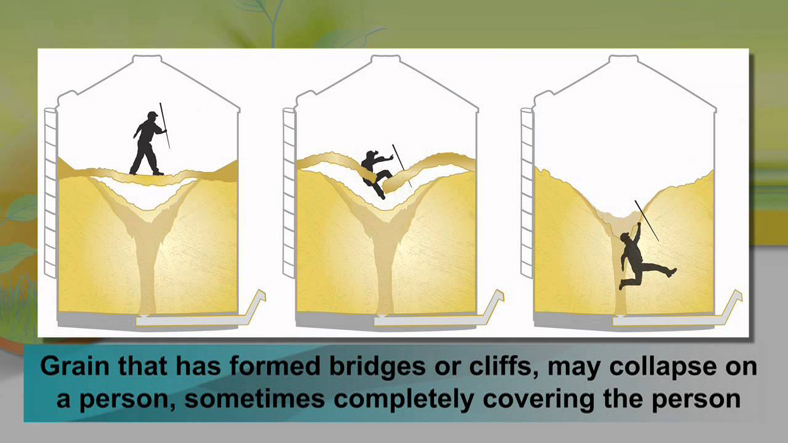

Remember, safety is always the first.

- Do not enter a grain bin unless it is empty.

- Do not enter a grain bin without protection.

- Cut down all the power before entering the grain bin.

What you need to check?

- Soil erosion around or under the edge of the grain bin pad can compromise the structural integrity of your grain bins.

- Frost heaves may be creating frost boils and sink holes around the bins and these areas will require management.

- Weeds and trash around the bins need to be cleaned. Weeds and trash around the bin will raise bugs and seduce pests, which will do harm to the grain bins. And may cause the stored grain mould.

- If you find the trace of bugs or pests, take timely measurement to ensure the cleanness around grain bins.

- Check the concrete foundation pad for cracks and structural damage and also examine the seal between the steel and concrete pad for integrity.

Inner cleaning of the grain bin

- Any residual grain debris left in the grain bin can be the source of insect or mould, and they will pollute your new harvest grain and make them gone bad. There is another passage about .

- The bins should be swept and vacuumed to remove all traces of dust, mould and old grain. Ensure that all fines, broken pieces of grain and dust are removed from any seams, ledges and flooring. Scrape, brush and thoroughly clean any areas that have caked on grain or mould and let dry thoroughly. Inspect the integrity of the grain bin walls for signs of rust and buckling. Rust caused by wet grain sitting against the grain bin sides can create rapid metal corrosion. Bins showing rust may have structural damage and should be inspected by an expert before the bin is put back in service. Repairs and repainting may be required.

- Check the bin seam, ensure there is no left in the seam. Make sure it is well sealed without leakage.

- The seal around the bottom of the bin where it is in contact with the concrete pad should be closely inspected as there is tremendous force applied to this area when the grain bin is full. Broken seals will result in moisture ingress and potential grain spoilage and can also decrease the lifespan of the bin by encouraging rust and metal corrosion.

- Checking all the supporting equipment to ensure they all runs well, if any of them break down, repair in time or replace a new one.