Performance requirements of grain storage for grain bins

In order to meet the food safety storage and grain storage process, the grain storage bin must have the following properties. The grain bin silo must be strong and durable. In addition to the load on the general building, it must also bear considerable food pressure. At the same time, the grain type, the method of loading grain, the height of grain loading and the side pressure of grain will affect the grain storage performance of the grain bin. Therefore, the grain storage bin must be sturdy and durable. The grain bin silo must have a closed, ventilated, fumigation tightness, ventilation, and fumigation is a very important means of safe grain storage. Sealing well is a prerequisite for ensuring good results in ventilation and fumigation.

what requirments does grain silo need to meet during the grain silo design process?

- Sealing well can reduce the contact between grain and the outside air, avoid the influence of external temperature and external humidity and the dyeing of insects, so that the grain temperature and moisture in the grain bin silo remain relatively stable; the rats can be prevented from harming during the grain storage, and the rats are not only losing a lot of grain, excreted feces pollute food, affecting the safe storage of food. A good airtight grain silo can maintain the effective concentration and ratio of gas in the grain silo, greatly enhancing the effect of fumigation and insecticide.

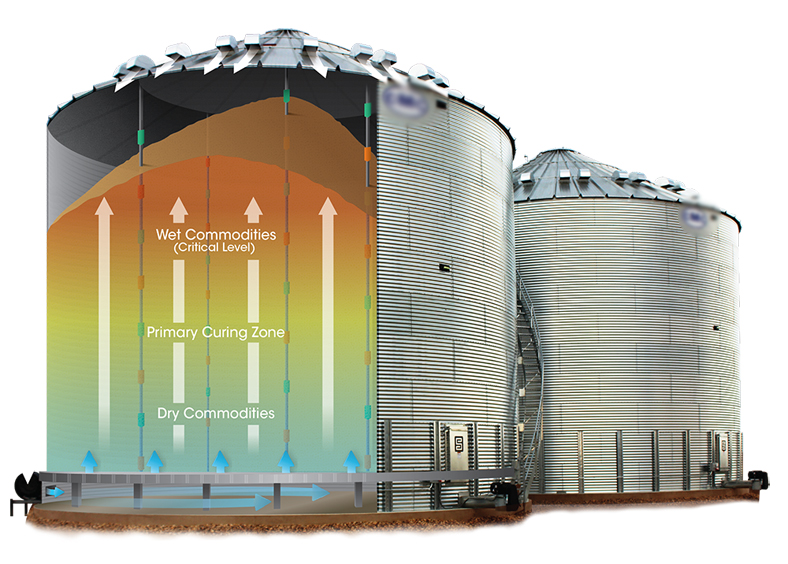

- Ventilation can be divided into natural ventilation and mechanical ventilation. The ventilation system is an essential grain bin accessories for each grain silo. It can promote the gas exchange of the grain piles, reduce the temperature and disperse the moisture, and prevent the heat and mildew of the grain storage. Its role is to create a low temperature environment, improve the performance of grain storage, balance the grain temperature, prevent moisture transfer, cool down the moisture, eliminate the odor of the grain pile, and also inhibit the occurrence and spread of insects and mold. The ventilation system needs to be specially designed. If combined with the circulation pipe, the air channel can also be used as a toxic air flow pipe and a gas diffuser for circulating fumigation. The axial fan of the silo can discharge the hot and humid air in the grain surface of the bin in time, not only accelerate the directional flow of air in the bin, but also prevent condensation caused by large temperature difference between the inside and outside of the grain bin. There are many ways to fumigation, but for grain bin design with a high grain level, a grain bin circulation fumigation system is generally used. It uses external force to distribute the poison gas evenly in the grain pile at a certain speed and concentration, which can effectively reduce the dosage and achieve the best effect. It is the preferred fumigation method for different types of silos and tall room warehouses in China.

- The densign of grain bin must have the function of preventing leakage and moisture. The grain is a porous colloid with strong adsorption and easy to absorb moisture. Once the grain moisture rises, it is easy to cause local or even full grain heat and mildew, and the bottom of the warehouse is back. The top leakage is usually the most likely to cause mildew and mildew in the grain. Therefore, the granary must be leak-proof and moisture-proof to ensure safe food storage. The grain storage process is rationalized, mechanized and automated.

- The quantity of grain storage is large, and the volume is large. In particular, the storage of grain in the warehouse is deep, which brings certain difficulties to the management of grain storage. Sometimes it needs rapid turnover, and the amount of work in and out of grain is large. Therefore, it is necessary to design a reasonable grain storage process with high degree of mechanization and automation. For silos, this is especially important. It has certain dustproof and explosion-proof performance. All food dust is flammable. In large-scale grain storage, especially in silo storage operations, adequate attention should be paid to dust explosion problems, otherwise it will cause huge losses that cannot be saved. Dust explosion accidents in silo storage have occurred internationally, especially in and out. Grain, bulk dumping operations should pay more attention.