In the construction of corn silos, a lot of factories will usually ask to add a primary cleaning tool. For most people, they don't understand what kind of tool it is and what can the machine does. What kind of functions can be played in the corn steel silo.

Why do you need a precleaning tool?

In fact, when you first hear about the tools, you will find that there may be some impurities in the corn before corn storage. For example, there may be corn cobs and some relatively large impurities in the hemp rope, so an impurity like this will cause great trouble for the later use of corn. If you add a primary cleaning tool to the corn steel silo, you will find that the tool will automatically remove all the impurities during the entire storage process, which will ensure that the corn is stored during the entire storage process. Cleanliness can be effectively guaranteed.

For example, we see that there are a lot of wines and starch, which will have certain requirements for the cleanliness of the raw materials. For example, corn husks and corn stalks cannot be found in the raw materials. After adding the primary cleaning tool to the corn silo, it is possible to screen out these impurities through this tool, which can effectively help the later production and processing. So this is why in many industries, a preliminary tool is added.

However, there are also some industries that specialize in storage, such as storing food, without any production and processing needs. When the steel silo is built, it is not necessary to add the primary cleaning tool, and only the transportation tool is required to satisfy the effect of the steel silo.

What do you need to pay attention to when using daily grain steel silos for corn storage?

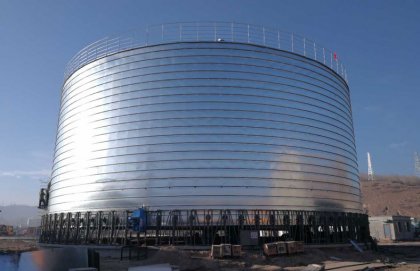

With the advancement and development of technology, grain silos have become the best way to store food. Grain steel silos have some of the characteristics that are quite advantageous for life.

Due to its thin wall and easy condensation, the spiral steel silo is skeptical about its ability to store grain for a long time. However, after investigation, some steel silo users have adopted appropriate ventilation and cleaning measures and improved. Management, the longest storage of wheat for more than 3 years did not occur bad grain phenomenon; some users due to supporting technology and management deficiencies, steel storage time of no more than 6 months of serious pest and bad food accidents. Therefore, Flyer gave a detailed explanation of the precautions for farmers when using the steel silo to store food. Please be sure to learn before using.

The water must not exceed the standard between the grain and the steel plate, and it must meet the national standard for safe grain storage. (If the water exceeds the standard, the moisture inside the grain pile shows a tendency to slowly dissipate from the inside of the grain to the surface, and then to the air in the gap of the grain. It is difficult for the grain moisture to escape from the air that does not flow. It is in the grain. Aggregate between grains, when the wet state reaches the saturation point, it begins to coagulate, which leads to fermentation and local temperature rise, which in turn causes the grain to release water and accelerate the corresponding fermentation process. When the ambient temperature rises, the grain is in the middle. Some dust, impurities, and especially organic impurities accelerate the above process, which seriously threatens the safe storage of grain. The food will rot. It must be ventilated to ensure that the food can breathe oxygen. Food is the organism of life and it has respiratory function.