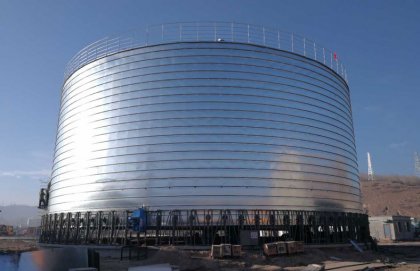

Cement steel silo is a tower for storing grain or cement. As a kind of closed bulk material storage equipment, cement steel silo is widely used for storing bulk materials such as grain, cement, fly ash and other materials that are afraid of rain and moisture. Because cement steel silo has the characteristics of rainproof, moisture proof and convenient use. Moreover, the tank body is equipped with a material level system (showing the position and amount of the material) and a hole-crushing device (to remove the material from being deposited for too long). The use of a screw conveyor can transport materials to various locations. It is easy to install, safe and reliable. It is an ideal bulk storage tank for various mixing stations. It is also the advantage of the cement steel silo that attract users.

However, as a professional steel silo supplier and construction manufacturer in China, Flyer Steel Silo has to remind users that although the cement tank is rainproof and moisture proof, you must pay attention to the purchase and use process. Specifically what you need to pay attention to, we made the following simple analysis.

Usually, we need to check the parts of the steel silo top, the wall and other leaks regularly. The general frequency is one month at a time. Of course, if there is time, the frequency is better!

For example, when the cement steel silo is full or is about to be emptied, we need to check whether there is any deformation of the lower wall, and also check whether there is rust in the sensitive parts such as the cross-legs, and then make the corresponding anti-corrosion treatment measures.

Of course, in addition to these, there are some details, such as the annual anti-loose inspection of the bolts, and check whether there is rot.

However, as a professional steel silo supplier and construction manufacturer in China, Flyer Steel Silo has to remind users that although the cement tank is rainproof and moisture proof, you must pay attention to the purchase and use process. Specifically what you need to pay attention to, we made the following simple analysis.

What you should pay attention during the use process?

- Most of the materials of cement steel silos are steel plates. Because they are often exposed to the air, they are definitely easy to corrode. Therefore, it is necessary to check the anti-corrosion work of cement steel silos, especially to check the anti-corrosion work on the surface of cement steel silos. Whether the silo integrity, thickness, smoothness is acceptable.

- The welding of cement steel silos is also very important. It is necessary to check whether the welds meet the requirements, whether the welding is firm and the welding is intact. During the use, remember to check whether the top of the cement steel silo is well sealed. Especially for users who store cement, it should be noted that once water enters the cement, it will cause unnecessary trouble.

- At the same time, it is necessary to check whether the side is sealed. This is also the place that users often ignore, thinking that as long as the top seal is OK, this is the wrong view. Be sure to pay attention in the future!

- If you accidentally make the material in the cement steel silo firm, I have a solution here. Generally, the small stones adhered to the side can be cleaned by the cleaning method we introduced earlier. If the discharge port is blocked, you can pump it inside. The air compressor at the general site can be used; if the blockage is very serious, the drill should be used. This type of usage is generally not recommended because it will not stop the material and cause losses.

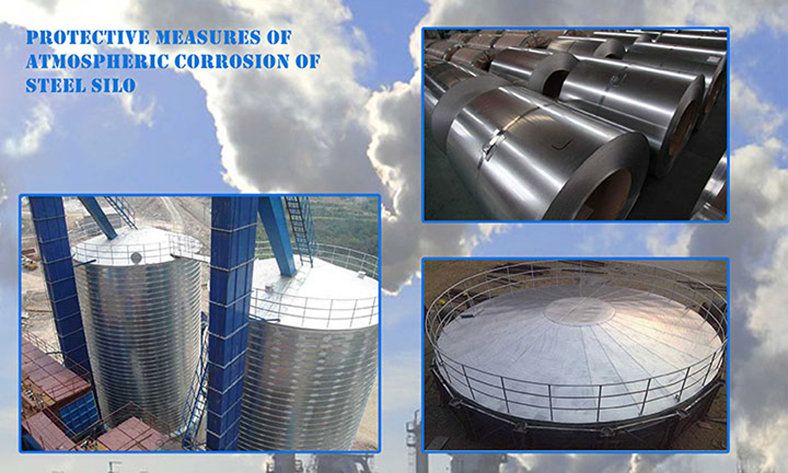

How to prevent steel silo from corrosion?

We all know that the steel silo is made of steel plate and the steel is metal. It may rot in the air or in a humid environment for a long time. We spend so much money to build a steel silo. I hope that he will use it for a longer time. Ok, so how to avoid the appearance of the corrosion of the steel silo has become our primary consideration!Usually, we need to check the parts of the steel silo top, the wall and other leaks regularly. The general frequency is one month at a time. Of course, if there is time, the frequency is better!

For example, when the cement steel silo is full or is about to be emptied, we need to check whether there is any deformation of the lower wall, and also check whether there is rust in the sensitive parts such as the cross-legs, and then make the corresponding anti-corrosion treatment measures.

Of course, in addition to these, there are some details, such as the annual anti-loose inspection of the bolts, and check whether there is rot.